Rehau is a leading manufacturer of plastic and metal-plastic products for utility systems and communications. Rehau pipes made of high-density polyethylene are used for water supply, drainage, and underfloor heating. Pipe sections are connected using fittings and compression sleeves, eliminating the need for seals.

Main types of Rehau pipes

The company produces several types of pipes with different purposes and physical characteristics. This allows you to select products that meet your operating conditions and budget.

RAUTITAN Stabil

This line features universal pipes that can be used for water supply to buildings and in heating systems. RATITAN Stabil pipes are made of cross-linked polyethylene and protected by an aluminum interlayer. They also feature a self-supporting PE-Xc layer, ensuring the pipe maintains its performance even if the aluminum is damaged.

Thanks to the high rigidity and ductility of the material, the pipes can be used in open wiring and retain their shape after bending. They are designed for a maximum pressure of 10 bar and temperatures up to 95°C. To ensure durability, they are pressure tested at 16 bar before shipping.

RAUTITAN Flex

These pipes lack an aluminum interlayer, making them highly flexible. They are made of durable, wear-resistant polyethylene that is impervious to corrosion. The material’s advantage is that it does not accumulate deposits. Rehau pipes are designed for the installation of main water supply and heating systems, including underfloor heating systems.

The maximum operating temperature of the operating fluid in RAUTITAN Flex pipes is 70°C, and the pressure is 10 bar.

Individual sections of the pipeline are connected using fittings and accessories of the appropriate size.

RAUTITAN Pink

This category is used exclusively for heating system mains. They are painted pink, making it easy to distinguish RAUTITAN Pink from other types. Rehau products are made of cross-linked polyethylene using molecular technology. The wall structure contains a layer based on

Ethylene vinyl alcohol (EVA), which protects against atmospheric oxygen. However, this makes the material unsuitable for drinking water. RAUTITAN Pink can be used at temperatures up to 95°C and pressures up to 9 bar.

RAUTITAN His

Simple, versatile pipes that can be used to transport water or heat transfer fluid. They are made of high-density polyethylene cross-linked using a peroxide method. This material is odorless and tasteless. RAUTITAN His pipes can be operated at a working pressure of 10 bar. The maximum The operating temperature reaches 70 degrees, but short-term heating up to 100 degrees is allowed.

RAUTITAN RAUTHERM

The line includes three product variants:

- RAUTHERM-S, with its distinctive red color, is used in the construction of heating systems.

- Yellow RAUTHERM-SL, designed for repairing and restoring pipelines without welding.

- Durable, thick-walled RAUPINK with an interlayer that prevents deterioration from contact with oxygen.

Rehau RAUTITAN RAUTHERM pipes are highly flexible and are often used for plumbing installations under baseboards.

Advantages of Rehau Pipes

Rehau products stand out from similar products due to the following advantages:

- The material is completely corrosion-resistant.

- The walls of Rehau polyethylene products have low thermal conductivity.

- Polyethylene can be used at high temperatures and pressures without losing its performance properties.

- The material from which Rehau pipes are made does not deteriorate with sudden temperature changes.

- The walls of Rehau pipes effectively dampen water flow noise.

- The material has a memory effect, ensuring absolute tightness of connections.

- Rehau pipes are resistant to ultraviolet rays and chemicals.

- Cross-linked polyethylene withstands dynamic and static loads.

- The service life of Rehau pipes is at least 50 years.

Thanks to the use of universal mounting elements, Rehau pipes are quickly installed. The flexibility of the material and a wide selection of shaped fittings facilitate the installation of complex pipeline configurations. By combining different types of pipes and fittings, it is possible to install a system along the entire length of a large object: from the heat source to the radiator.

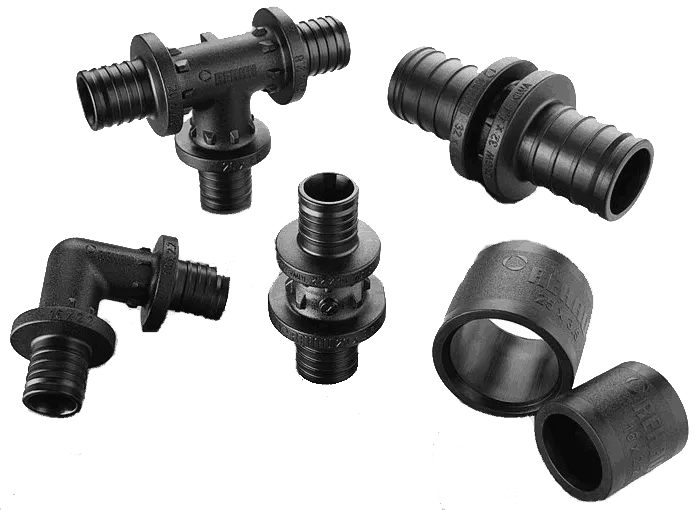

Rehau fittings

Threadless fittings are produced using polyphenylsulfone, a polymer with superior strength properties to metal counterparts. Our wide range of products is divided into the following groups:

- Mounting sleeves;

- End caps;

- Distributor manifolds;

- Elbows;

- Brackets;

- Couplings;

- Tees;

- Guides;

- Battery connection tubes;

- Fixing channels;

- Threaded adapters;

- Connecting fittings;

- Fire collars.

The use of Rehau fittings allows for the quick installation of water supply or heating systems, as well as the repair and modernization of existing pipelines.

Installation

The assembly technology for Rehau metal-plastic or plastic systems is similar to that for polypropylene products. A special Rautool tool is required for connecting pipes with diameters of 14-100 mm. Inexpensive hand-operated tools and professional equipment powered by electricity or batteries are available.

Only Rehau polymer fittings of the appropriate diameter may be used to connect sections.

Elements equipped with a sliding sleeve can be connected without inspection.

Before installation, the following steps must be completed:

- Cut pipes of various lengths and cross-sections according to the drawings;

- Select fittings to connect the pipeline sections.

Pipe installation using sleeves and fittings is performed in accordance with the instructions included with the Rautool device.

Procedure:

- Spread the tool handles so they are at a 90-degree angle to each other.

- Attach a nozzle sized to the expander’s diameter to the pipe section.

- Slide the nozzle until it fits snugly on the expander’s pin.

- Place the sleeve onto the tube. It attaches to the fitting with the bevel facing toward the butt joint.

- Insert the tube into the expander, increasing its diameter.

- Insert the fitting into the expanded end.

- Feed the sleeve toward the fitting.

- Using a special tool, press the sleeve firmly into the fitting.

The result is a reliable, sealed connection that can withstand pressures in excess of 10 bar.